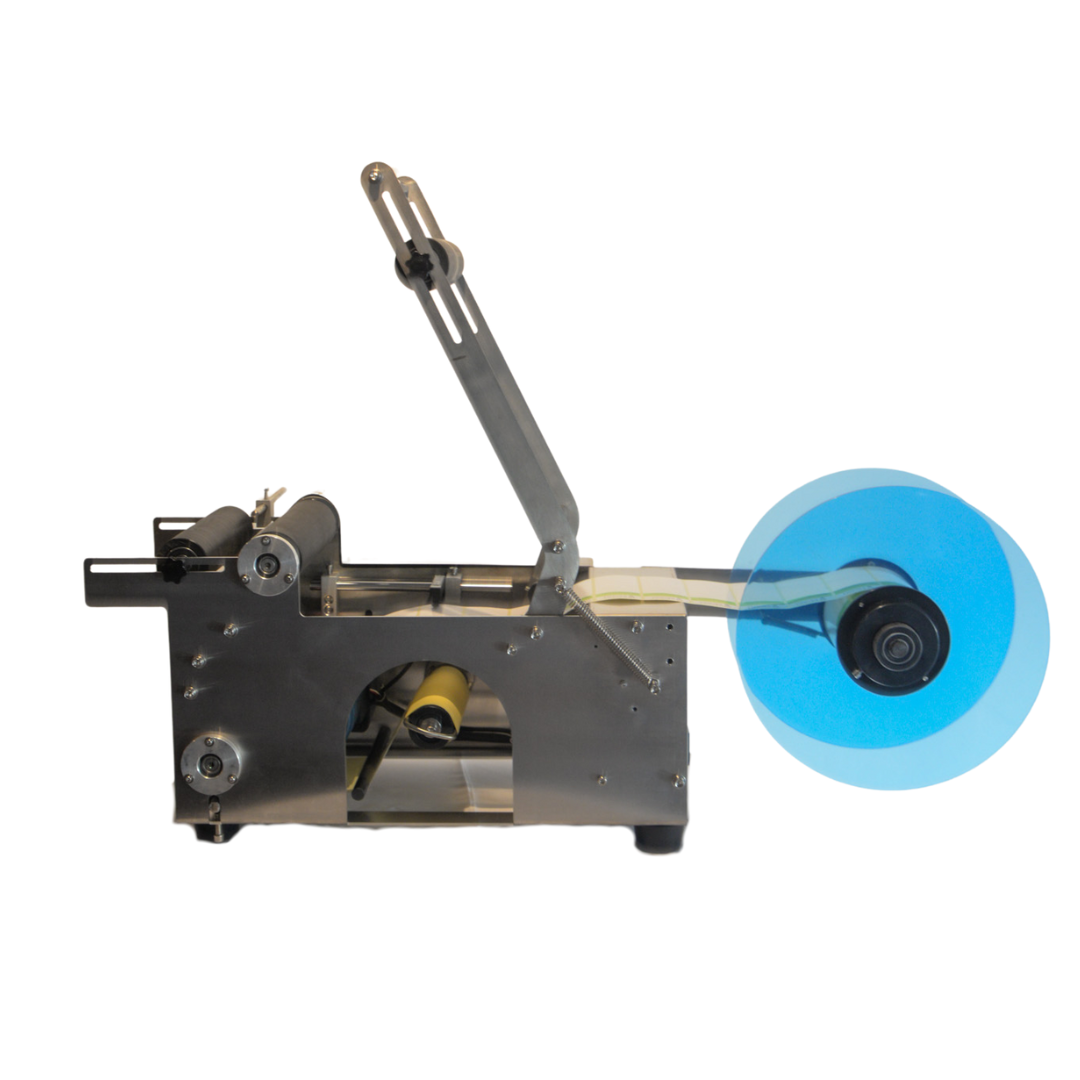

Semi-Automatic Round Bottle Labeling Machine

Couldn't load pickup availability

Description

Introducing the Semi-Automatic Round Bottle Labeling Machine, your ideal semi-automatic solution for efficiently labeling round bottle products across various industries, including daily chemicals, food and beverage, pharmaceuticals, and more.

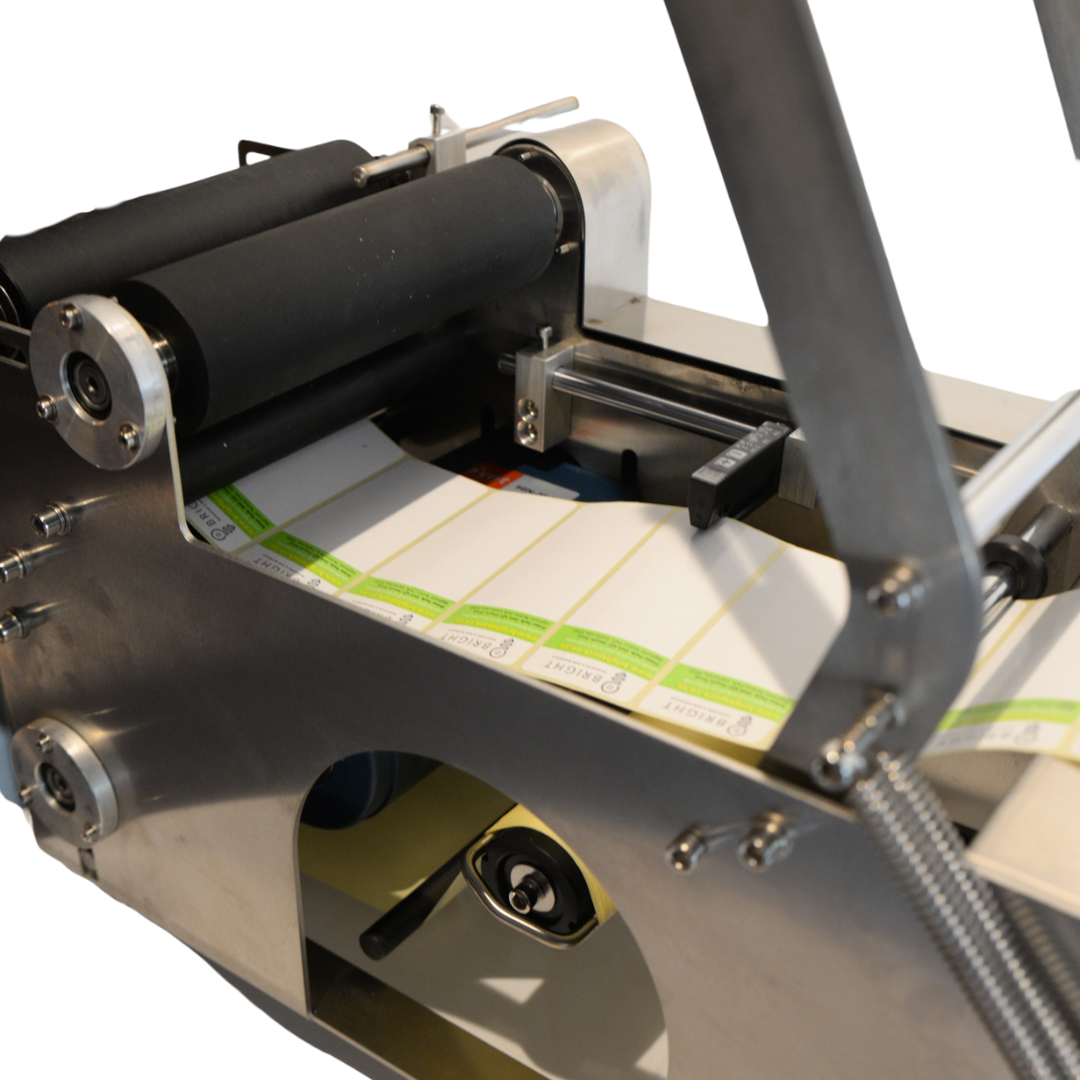

This versatile machine accommodates different bottle sizes with ease, thanks to its strong adaptability and adjustable label length feature. The label's light eye sensitivity can be finely tuned to ensure precision labeling every time. Constructed from high-quality stainless steel and aluminum profile materials, this machine not only meets GMP environmental standards but also guarantees durability and resistance to rust or contamination. All control components adhere to international standards and have undergone rigorous factory testing, ensuring top-notch quality and long-lasting performance.

With a maximum output of 50 pieces per minute for non-positioning labeling, our Round Bottle Labeling Machine is designed to streamline your production process while maintaining the highest standards of accuracy and efficiency.

Technical specifications

-Labeling Speed: Up to 50 pieces per minute

-Bottle Diameter Range: 12 mm - 150 mm

-Power Supply: 220 V +/- 5% 50Hz

-Dimensions: 640 x 350 x 460 mm

-Weight: 24kg

Key Features

-High Efficiency: Capable of labeling up to 50 bottles per minute, this machine ensures your production stays on schedule without compromising quality.

-Versatile Sizing: Accommodates bottles with outer diameters ranging from 12mm to 150mm, providing flexibility for various product lines.

-User-Friendly Operation: Simple to set up and easy to operate, this machine requires minimal training, allowing your team to quickly adapt and maintain productivity.

-Durable Construction: Built with high-quality materials, this labeling machine is designed to withstand the rigors of daily use, ensuring long-lasting performance.

-Precise Labeling: Achieve consistent and accurate labeling every time, enhancing the professional appearance of your products.

Equipment catalog

Caution

-Use Correct Bottle Sizes: Ensure the machine is adjusted for the appropriate bottle size to avoid misalignment or damage to the labels or bottles.

-Turn Off Power Before Maintenance: Always switch off and unplug the machine before performing any cleaning, adjustments, or maintenance.

Keep the Work Area Clean: Ensure the area around the machine is clear of obstructions to prevent accidents and maintain smooth operation.