SPRALL Inclined Horizontal Pneumatic Mixer 200

Couldn't load pickup availability

Description

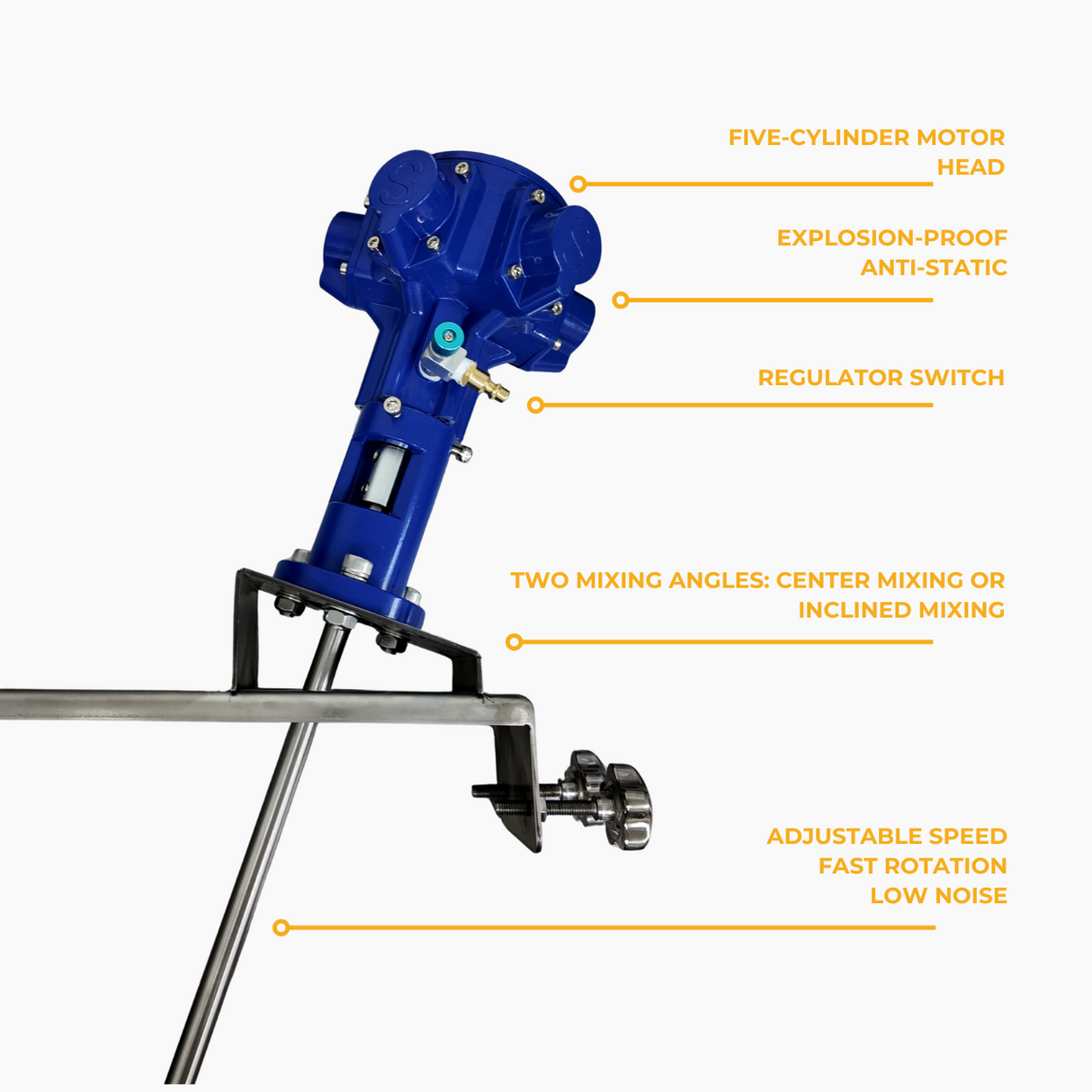

Built for versatility and performance, this pneumatic agitator is engineered to agitate standard 200L drums—whether sealed or open. With its drop-down impeller design and adjustable mounting, it offers powerful mixing with minimal effort.

PLEASE NOTE: This machine requires the use of an air compressor (not included). The compressor air requirements are 6 bar @110L/minute.

Technical Specification

¾ HP Pneumatic Motor: Reliable, high-torque mixing power

Compressor Air Requirements: 6 bar @110L/minute

Speed Range: Up to 1300 RPM for efficient agitation

Fits 200L Drums: Designed specifically for standard drum volumes

Drop-Down Impellers: Fits through drum bung hole for sealed drums

Dual Mounting Options: Angled for closed drums or vertical for open tops

Heavy-Duty & Versatile: Ideal for continuous or batch mixing

Stainless Steel Construction: Durable and easy to maintain

Explosion-Proof: Safe for use in hazardous environments

Applications: Paints, chemicals, oils, cosmetics, food & pharma

Cleaning + Repairs + Warranty

Keep the mixing shaft and paddle clean after each use. The cylinder, bearings and guide rods need to be lubricated regularly. If your machine is more than 5 months old, open the motor head and add grease.

Pneumatic Mixer Machine Warranty: We offer a 6-month warranty on our Pneumatic Mixer Machines, effective from the date of purchase. This warranty covers defects in materials (factory faults) or workmanship under normal use and maintenance. In the event of a factory fault or material defect, the service fee for booking the machine will apply. However, it will be refunded if the fault is determined to be due to factory defects.

Please note that the warranty does not extend to damage caused by misuse, improper handling, or unauthorised modifications. Proof of purchase is required to process any warranty claims.

Machine Refunds and Repairs: Once used, machines are not eligible for refunds or returns. If the machine has been used, or it is not in its original packaging, damaged or missing any parts or accessories, we cannot accept it for a refund or return. For any other faults or issues, you may send the machine to us for inspection via delivery or courier.

Please note: A service fee of R450 (excluding VAT) must be paid prior to booking the machine in for inspection or repairs. This fee covers the initial assessment and repair service. This fee is fully refundable in the case of manufacturing defects. However, it will not be refundable for issues resulting from misuse or wear and tear. The inspection and fault analysis process may take 3-5 working days. Please note that spare parts are not included in this fee and will be provided based on a formal quotation.

We kindly request that all machines be brought in clean for ease of handling.

All machines requiring repairs must be booked in through our designated process. Please ensure that all necessary details are provided when booking.

Manual

Click HERE to view the manual.

Equipment Catalog

Precaution

Keep the gas source clean and make sure that the gas does not contain water or oil.

Keep the transmission part of the mixer out of direct contact with people.

After mixing, unplug the air source according to the operating sequence.